Revolutionary technology

At Candela, we develop electric motors, sensors, software, and hardware in-house, creating a fully optimized vessel and delivering a superior experience for both users and operators. In 2014, our founder Gustav Hasselskog gathered a team of experts to tackle the challenge of making electric boats that are better than fossil-fueled boats in terms of performance. The solution was hydrofoils—an invention decades old—enhanced with active stabilization.

Powering the future

Advanced hydrofoil tech

Whisper-quiet

electric drive

Long

electric range

Zero emissions,

zero oil spills

Technology that powers a silent revolution at sea

At Candela, we design and manufacture the world’s first commercially available electric hydrofoil craft. By flying above the water’s surface and reducing friction, our boats achieve long range and high speeds, dramatically lowering operational costs compared to diesel-powered vessels. This makes the transition to sustainable fleets both feasible and attractive.

At the core of our technology is the actively stabilized, computer-controlled C-FOIL system, paired with the highly efficient direct-drive C-Pod motor family. Together with our full carbon fiber design, this groundbreaking innovation delivers performance never before seen in electric boats, while offering passengers a superior and smoother experience in rough seas.

C-Pod electric drive

The Candela C-Pod is an ultra-efficient, low-maintenance drive unit with dual submerged motors. It provides quiet, gearless operation, low operational costs, and enough power to drive the boat at impressive speeds.

Our 100% electric motor

Foiling system

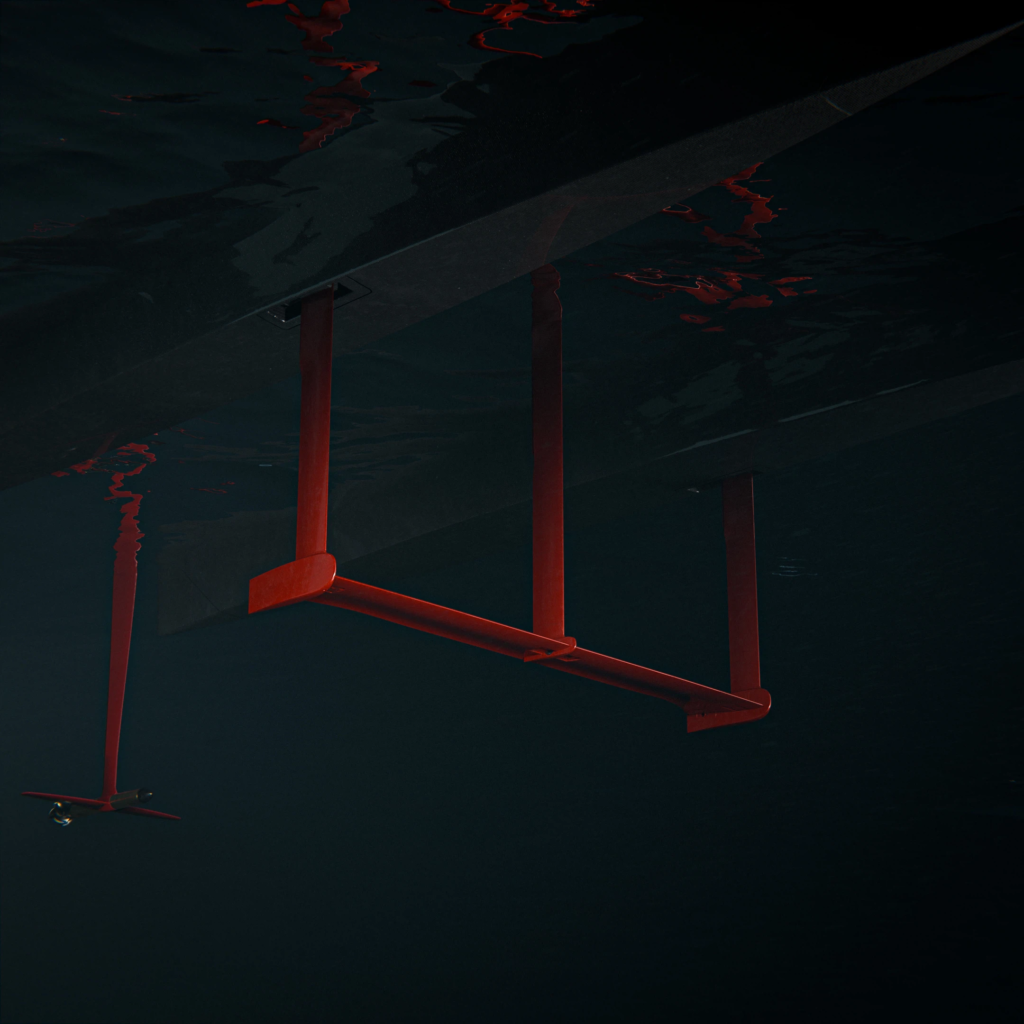

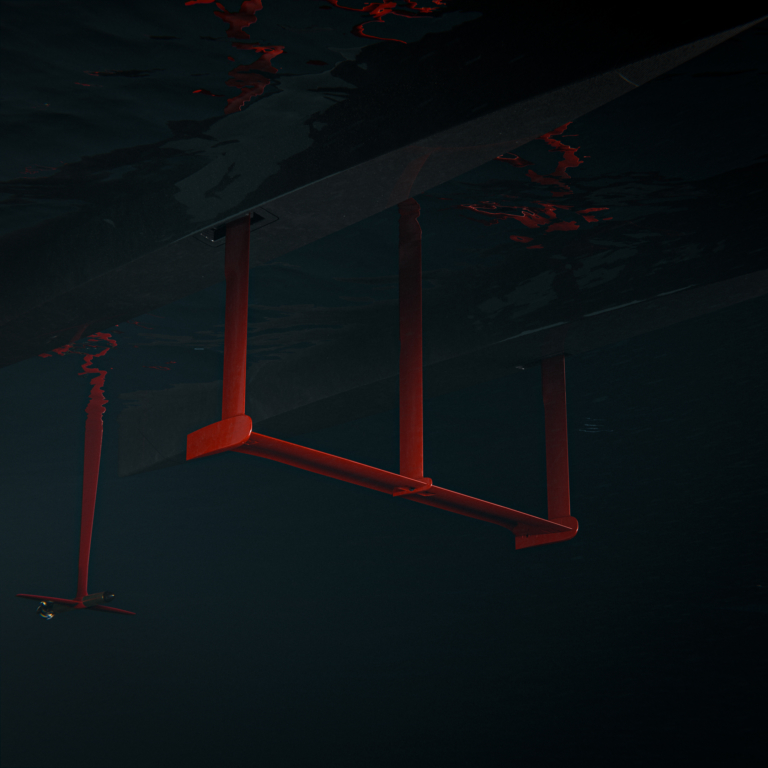

Candela’s submerged, computer-controlled hydrofoils lift the boat above the water, cutting energy use by 80%. This allows for longer trips on battery power and provides a smoother ride than regular boats.

Our foiling system

Candela Tech Talks

Explore Candela’s cutting-edge technology in our Tech Talks series, where experts break down the C-Pod motor, advanced foiling system, and flight controller that power our electric hydrofoil boats.

Questions?

Here are the top five.

How do you keep the boat stable?

A Candela is an inherently unstable craft, made artificially stable by using software and computer power. We use an advanced control system that adjusts the hydrofoils’ angle of attack 100 times per second in order to provide a smooth ride in waves and in windy conditions. Sensors situated in the bow our of our vessels measure wave height and feed this information to our Flight Controller. Additionally, height, roll and pitch data are added. The result is a boat that provides a much more comfortable experience than conventional craft.

What are the maintenance requirements?

In terms of service costs, a Candela requires less service than a fossil fuel equivalent due to fewer moving parts. Therefore, there’s no need for regular maintenance like winterization, filter and oil changes, associated with fossil fuel engines.

What materials do you use for the hull?

We exclusively use carbon fiber in all of our boats. Currently, there are no alternative materials that meet our expectations of stiffness, weight, longevity and cost.

Which foil configuration and wing profile do you use?

All Candela vessels feature fully submerged hydrofoils. Meaning, we use one large, straight main foil near the center of gravity and either one (Candela C-8) or two (P-12) smaller foils at the aft, attached to the propulsion unit. Additionally, all Candela boats are equipped with retractable foils for trailering, storage, and shallow water operations.

In terms of the wing profile, to strike the optimal balance between efficiency and performance, we have developed our own proprietary foil shape. To minimize the environmental footprint of carbon fiber and batteries used in our vessels, we build them for longevity. Furthermore, by keeping the boats light, we require less carbon fiber and smaller batteries, resulting in significantly lower energy consumption compared to our competitors.

What parts of the technology do you develop in-house?

Candela is a tech company with over 50 engineers. To provide our users with the best possible experience, we develop our C-Pod motors, software, and hardware, including the foil control software and sensors, all in-house. We’ve chosen this challenging but rewarding path for several reasons. First, we aim to make boating frictionless—the software should seamlessly integrate with the boat’s features. We weren’t satisfied with the third-party options available. Second, remote software updates should be easy to perform, offering continuous improvements for an increasingly robust user experience. Lastly, if you need assistance, our service team can remotely access your boat’s system to help.

Overview

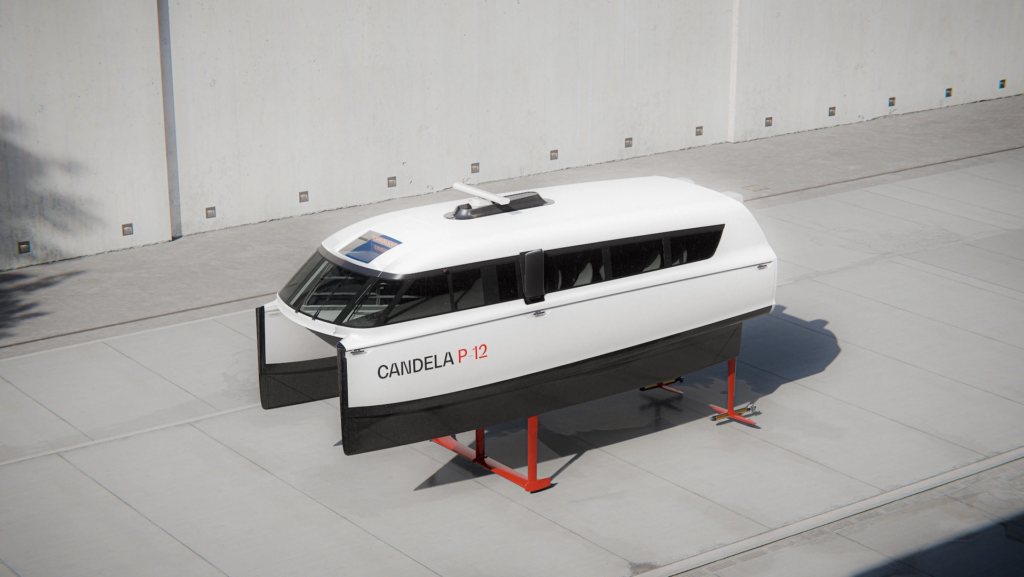

Overview  P-12

P-12  Overview

Overview  C-8

C-8  C-7

C-7  Overview

Overview  Electric motor

Electric motor  Foiling system

Foiling system